NPI - New Product Introduction

NPI Improves Quality and Efficiency

The NPI progam covers all the activities within the company to define, develop and launch a new product. Following an well-organized and planned NPI proces can optimizes product design, system assembly, material supply, and flawless quality, efficient mass production and Faster Time-to-Market.

Our engineers work closely with our customers' engineers on issues related to the prototyping of new products. We don't just care about electronic components and subsystems, we also help:

- Electrical engineering, including PCBA design review, layout modification and material procurement;

- Mechanical engineering, including fixture manufacturing, plastic and metal casing design, and packaging design;

- Test design, including ICT / ATE testability analysis, fixture management and tester programming.

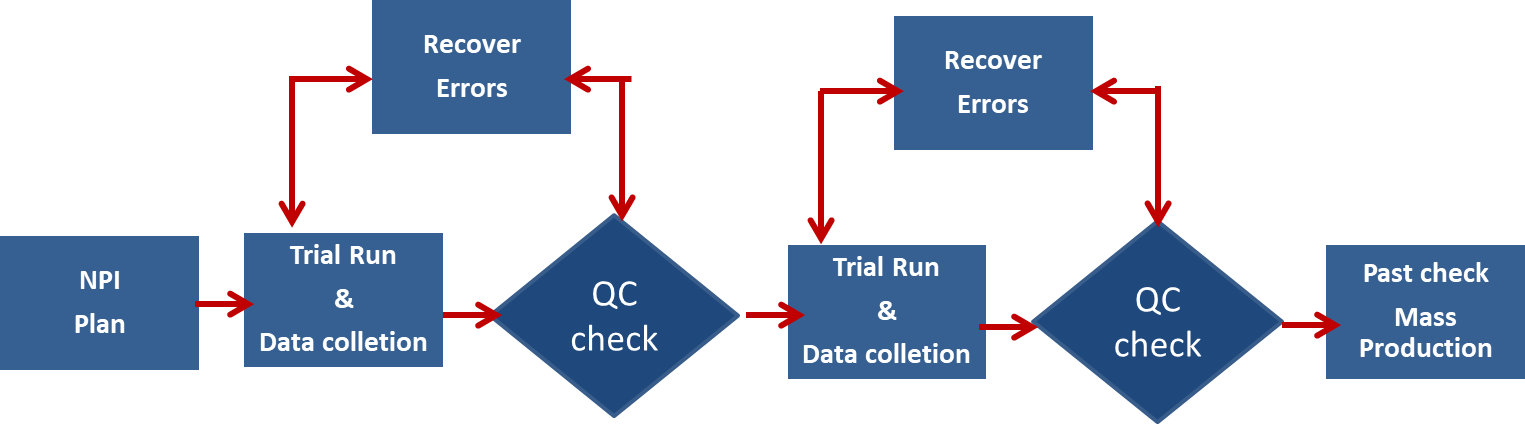

New Product Introduction Process

We have a rigorous NPI-new product introduction service process to ensure the quality of new product introduction. But we still allow flexibility, so that the customer's design changes can be immediately updated into the sample production. Throughout the new product t introduction process, our professional teams in each department will carefully monitor any foreseeable problems that may arise during the NPI and try to completely resolve them before formal mass production.

From the moment we receive your product design, we act as your professional manufacturing service consultant. Our production, engineering, materials, and quality control departments work with your engineering design team to carefully control every step of the process to ensure smooth and efficient operation and achieve high-quality, low-cost and fast time-to-market excellence.

In the initial NPI planning phase, all related departments including production, engineering, materials and quality should be working together to carry out the preparations required for the first trial run. These tasks usually include:

- Preparation of BOM bill of materials;

- Create the appropriate jig;

- Program production and test machines;

- Establish a quality monitoring process.

During the first trial production period, we collect important key data, and our engineers will evaluate whether the trial production product is acceptable and determine the improvement items needed for the product and production process.

Once the improvements required for the first trial run have been verified, you can rest assured that you can start mass production in the most efficient way now.

Once the improvements required for the first trial run have been verified, you can rest assured that you can start mass production in the most efficient way now.