Our Top Quality Goal = Customer Satisfaction

Quality, Responsiveness, Friendly Service

ISO 9001, 13485, 14001 Certified EMS Taiwan

Our Quality Strategy

At DDC, we are convinced that quality and manfacturing yield imeans competitiveness, so we ensure that our quality policy always meets our quality goals: to ensure that we provide our customers with the best products and services and make them more competitive. Our core quality values focus on teamwork and commitment, prevention of loss and continuous improvement. We can continue to innovate, implement and upgrade our quality plans and systems, and thinking about quality is never just an afterthought.

Our quality certifications

ISO 9001: 2015

International Quality Management Standard Certifications

ISO 13485: 2016

Medical devices -- Quality management systems

ISO 14001: 2015

Environmental Quality Management Systems

Declaration of Metal Conflict-Free

Our Company is taking and will take due diligence within our supply chain to assure “DRC Conflict-Free” for the metals of gold (Au), tantalum (Ta), tungsten (W), and tin (Sn) are not derived from or sourced from mines in conflict areas of the Democratic Republic of Congo (DRC), or illegally taxed on trade routes, either of which are controlled by non-governmental military groups, or unlawful military factions. Trade routes not confirmed to be “Conflict Free” include exports from the DRC, exports through Rwanda, Uganda, Burundi, Tanzania, Kenya (countries of whom the U.N. Security Council note are global export routes for DRC-mined minerals), as well as foregoing minerals sourced from any conflict areas under condition of armed conflict ,human rights abuses or other illegal methods.

Click here to download this declaration letter

"Declaration of Metal Conflict-Free Report"

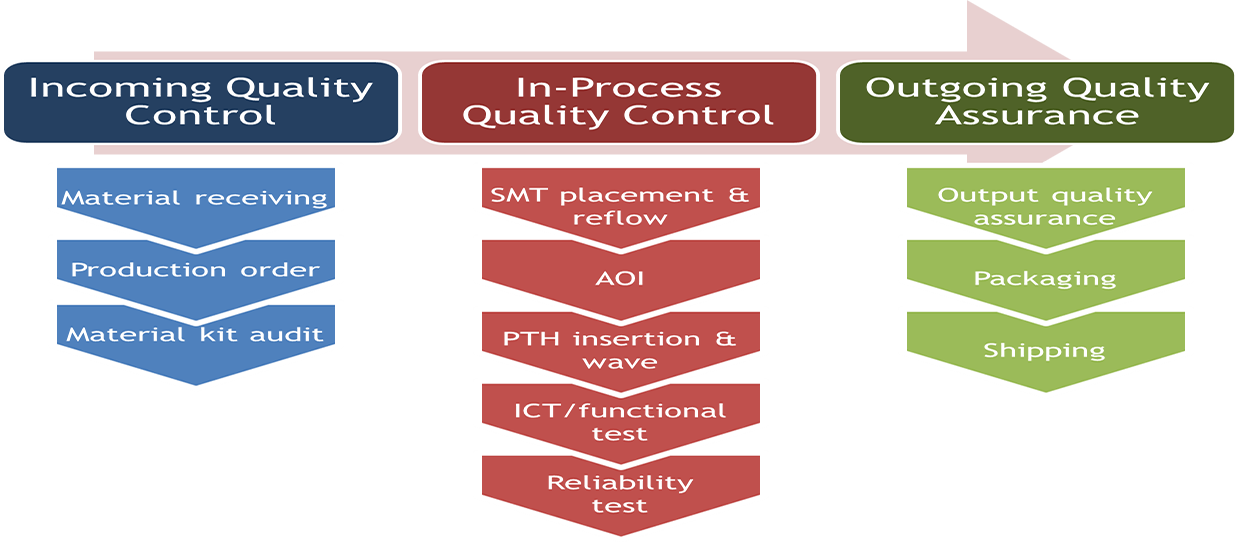

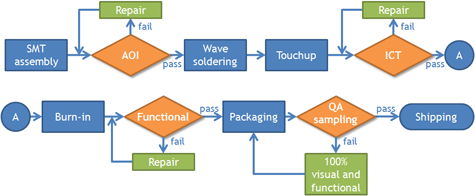

Quality Control and Inspection Process

Adhering to the spirit of TQM's comprehensive quality management system, we have implemented education and training for quality control personnel and online operators. From IQC -Incomming Quality Control, IPQC - In Process Quality Control, and OQC - Outgoing Quality Control, we are checking the quality for customers at every level.

Defect Prevention

We believe that preventing defects before they occur is more important than correcting them after the fact. Our proactive thinking and positive attitude can ensure that no precious time or resources are wasted.

-

Process Design and Review

The main goal of our manufacturing process design is to minimize any defect factors that may affect the next manufacturing stage. Our processes are frequently reviewed and improved to ensure compliance with specified specifications and performance. Many of our online test equipments and procedures are at the core of our overall process design strategy.

For example, the manufacturing of the server board must follow the MPI - Manfacturing Process Instructions, it will be further inspected at multiple quality inspection points to ensure that the defective product will not be shipped out.

-

Operator Qualification Verification

In a highly complex production environment with multiple products coexisting and frequent process changes, it is extremely important to have a system for operator qualification verification.

In DDC, in order to ensure that operators can access and absorb professional knowledge to achieve a certain degree of qualification, each operator must receive specific job training and retraining each year to ensure that the assigned tasks can be correctly performed by the operators:

Statistical Process Control

Statistical Process Control System is by collecting all kinds of quality information in the process in real time, applying statistical methods and control laws, monitoring the process capability, so as to provide early warning of abnormal trends and achieve the purpose of improving and controlling product quality

Continous Improvement Plan

We firmly believe that quality doesn't stop at following established rules; we must constantly seek low-cost and low-risk and high quality solutions. Our operators, engineers, and managers are working together to find the most advantageous method to avoid or avoid the defect-inducing factors in the control process.

The characteristics of continuous improvement are deeply rooted in the work culture of DDC. For example, the quality competition between different production groups and the active participation of the team of various improvement plans proposed every month.

Failure Analysis

Our comprehensive testing and defects analysis capabilities can help you diagnose design and manufacturing issues.

5S Implementation

-

5S is the visual management system can effectively manage anything in orderly manner, it can be used for manufacturing, warehouse, office, manual, or computer files, etc.

The 5S was invented in Japan, the five 5S are Seiri, Seiton, Seiso, Seiketsu, and Shitsuke. If translate into English, they are Sort, Set in Order, Shine, Standardize, and Sustain. The benefit of 5S are improve productivity and Safety, reduction in Waste, etc.

Our entire factory implements the 5S. We follow the spirit of 5S to establish disciplines, ensure safety, improve efficiency, reduce poor quality and waste.